Surface Profile vs Coating Thickness: Where Most Specs Break Down

Surface profile and coating thickness are usually treated as separate line items.

One is created during blasting.

The other is measured after painting.

In the field, they’re inseparable. And when they’re mismatched, even slightly, coating performance suffers in ways that don’t show up until months later.

This is where many otherwise “by-the-book” jobs quietly go wrong.

Profile Is Not Just Roughness

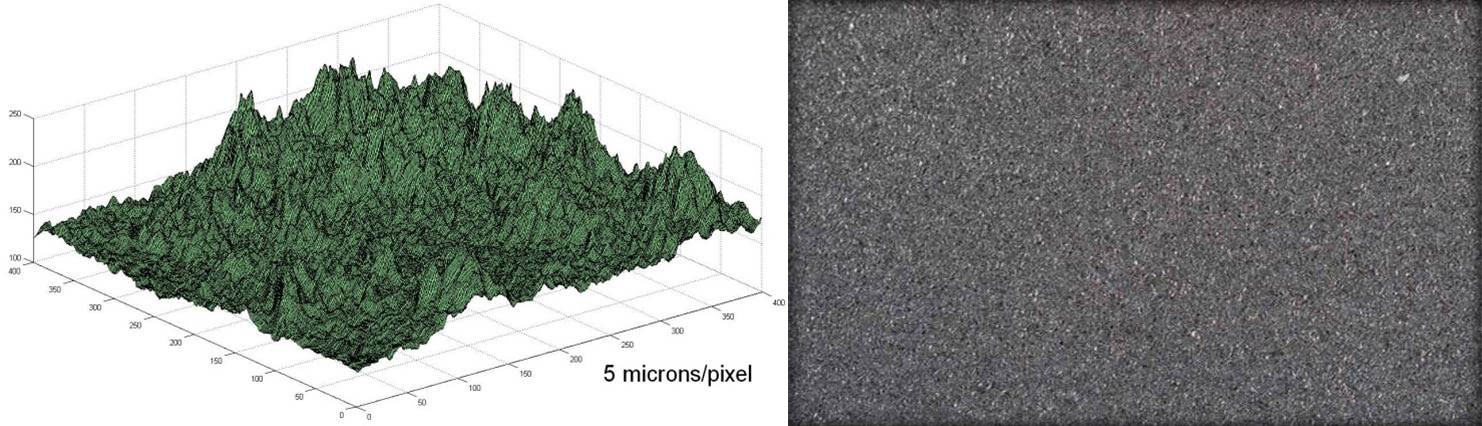

Profile is often described as “how rough the surface is,” which is technically true and practically useless.

What matters is shape, depth, and consistency of the peaks and valleys created by blasting. Two surfaces can measure the same average profile and behave very differently once coated.

Sharp, angular peaks behave differently than rounded ones. Uniform profiles behave differently than patchy ones.

Coatings respond to geometry, not just numbers.

Coating Thickness Has to Match the Profile

Every coating system has a practical relationship with surface profile.

If the coating is too thin relative to the profile:

peaks remain exposed

early rust forms at high points

failure starts before it’s visible

If the coating is too thick relative to the profile:

the coating bridges instead of bonding

solvents get trapped

cure problems follow

Both situations technically “meet spec” in many cases. Neither performs well long-term.

Why Average Profile Measurements Mislead

Most profile measurements report an average.

Averages hide extremes.

A surface with aggressive peaks and shallow valleys can average out to the same number as a surface with moderate, uniform texture. Coatings don’t experience averages. They experience the highest peaks first.

This is why inspectors and applicators can both be “right” and still end up with failure.

Over-Blasting Creates Its Own Problems

It’s easy to assume more profile equals better adhesion.

That logic breaks down fast.

Excessive profile:

increases coating demand

creates sharp peaks that are hard to fully wet

raises the risk of early breakdown at peak tips

On thin steel, aggressive profile also increases heat input and distortion risk. That damage happens before paint ever enters the picture.

Under-Blasting Is Just as Common

On the other side, insufficient profile is often missed entirely.

The surface looks clean. The coating looks good. Adhesion seems fine until it isn’t.

Under-blasted surfaces rely heavily on chemical adhesion alone. When environmental stress shows up, there’s nothing mechanical backing it up.

Failures here tend to show up later and spread quietly.

Thickness Specs Aren’t Performance Specs

Film thickness specs are often written to be easy to verify, not to ensure performance.

Hitting a target mil range doesn’t guarantee:

proper wetting of profile

uniform film distribution

compatibility with surface geometry

Thickness numbers without profile context are incomplete instructions.

Where Timing Makes the Mismatch Worse

Even a well-matched profile and coating system can fail if timing slips.

Flash rust, contamination, or moisture can change the effective profile between blasting and coating. Peaks dull. Valleys trap residue.

If you’ve already read about flash rust and inhibitor limitations, this is where those issues compound.

Rust Inhibitors in Wet Blasting: What They Do & Where They Fail — Can Be Done Mobile Blasting

Field Reality: Specs Don’t See the Whole Surface

Specifications describe intent. The field delivers reality.

Surfaces aren’t uniform. Edges behave differently than flats. Welds behave differently than plate. Repairs behave differently than original steel.

The best crews don’t chase numbers blindly. They watch how the coating behaves during application and adjust before problems get locked in.

What Experienced Operators Watch Instead

Professionals pay attention to:

how easily the coating wets the surface

whether peaks disappear or remain visible

how the film flows around geometry

how the surface looked immediately before coating

Those observations often matter more than a single measurement.

Final Thought

Surface profile and coating thickness are not independent variables.

They form a system. When one changes, the other has to respond. When they don’t, failure is baked in early, even if every box gets checked.

Understanding where specs simplify reality is part of doing work that lasts.

Next Up

Over-Blasting vs Under-Blasting: How Both Shorten Coating Life

Why “too much” and “not enough” surface prep often fail for different reasons—and how to spot each before it’s too late.